Our Strengths

Our Strengths - The Control of the Manufacturing Process

Our strengths - Optimised Design

We collect the data, characteristics of failures, and design defects of the equipment we worked on, conduct our quality evaluation, and review the design of the purchased/manufactured parts. On the basis of maintaining the functions and safety of the whole machine, determine the levels of parts for the cost and performance.

When selecting bearings, the clearance level and retainer material will be strictly controlled;

When selecting seals, the finishing parameters, linear velocity, and clearance must be strictly controlled.

Our Strengths - Top Partner Manufacturers Around the World

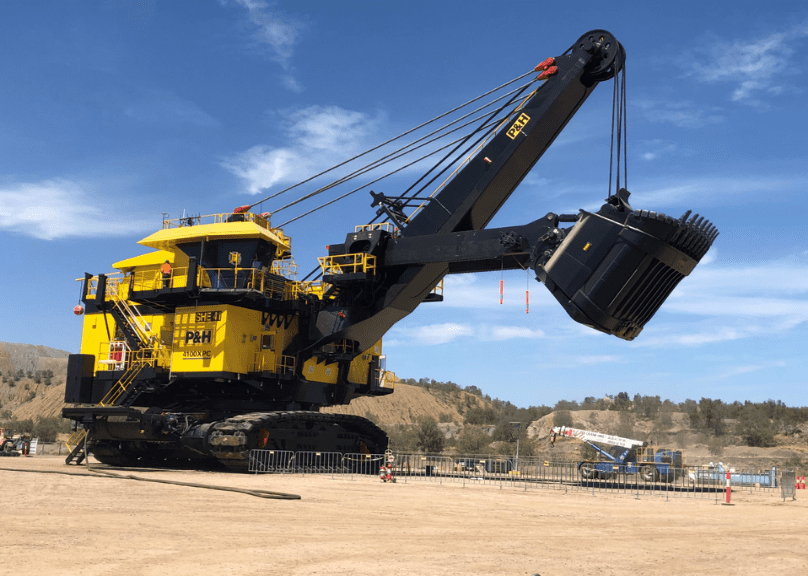

BFG is also the main supplier of transmission parts for open-pit mining equipment of GE, CAT, JOY global, Komatsu mining equipment (USA), ZF, Siemens, Terex, etc.

Our Strengths - Equipment Upgrade and Testing Platforms

Our company has 6 T-282B trucks and one 4100 electric shovel as a testing platform for whole truck system upgrade experimentation and testing.

Our Strengths - Excellent Spare Parts Suppliers

Our Strengths - Professional Focus

During over 10 years of continuous cooperation and the accumulation of knowledge, learning, and innovations with international counterparts, we have formed an efficient, professional R&D team. Our maintenance team consists of international experts, domestic engineers, and senior technicians, ensuring the high quality and continuous improvement of our products.

We have repaired the following equipment:

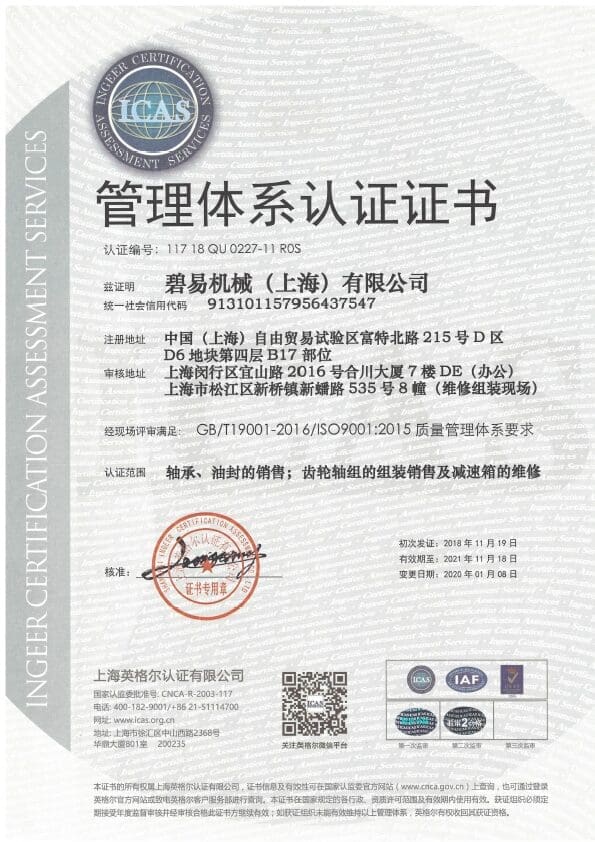

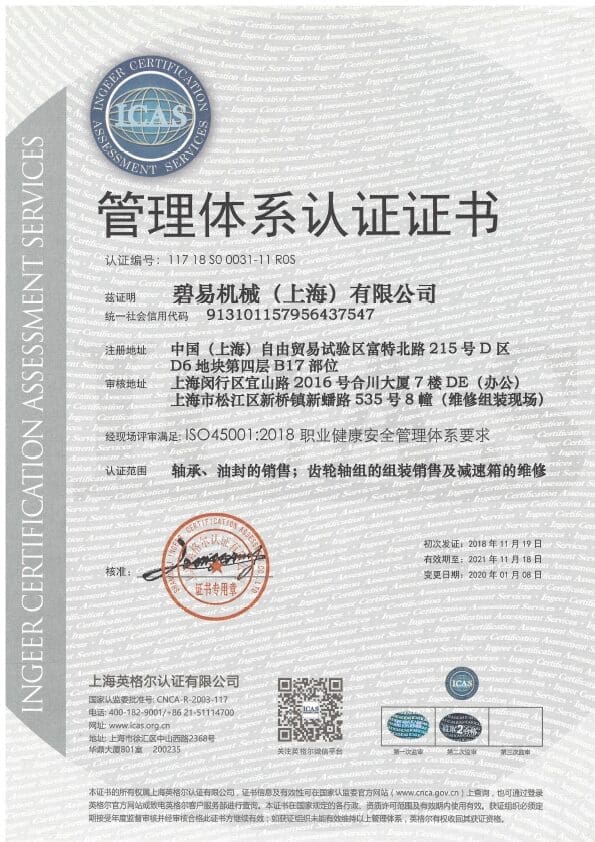

Our Strengths - Quality Control System

Our Strengths

1. Quality control of the maintenance

2. Service

Our Strengths - Advanced Design

We ensure pure rolling gear engagement under heavy and overloaded conditions, leveraging our extensive maintenance experience. We combine long-term analysis and monitoring of customer operations with the latest software for analysis, simulation, and testing. This approach guarantees significant improvements in cost-efficiency and performance over five years. Our technical advantage ensures that each maintained gearbox operates safely for over three years without disassembly, maintaining a consistent record. Our dedicated maintenance experience, combined with customer-specific analysis, ensures substantial improvement in overall cost and efficiency over a five-year period.