Maintenance, Rebuilding and Remanufacturing

Professional maintenance skills and troubleshooting experience ensure we play a leading role in the repairing and rebuilding of transmissions of large mining equipment. The performance of our equipment is equal to or even exceeds the originals in many cases.

We hired senior technicians from the USA to supervise and train our team for the maintenance, assembling, and commissioning on-site, which was a great improvement for our team. We have strict procedures in the shop to ensure the quality of maintenance.

We have repaired 12 units of 7495 electric shovel swing gearboxes for our customer in Namibia.

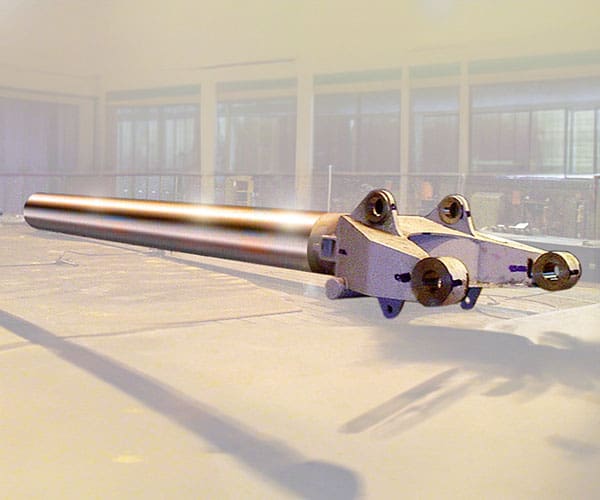

We have supplied and repaired 12 units of 7495 propelling gearboxes. We have supplied two upgraded Dipper Handle.

The handle is fabricated from a single billet for reduced stresses and extended life.

We have repaired the following for our customer in Namibia

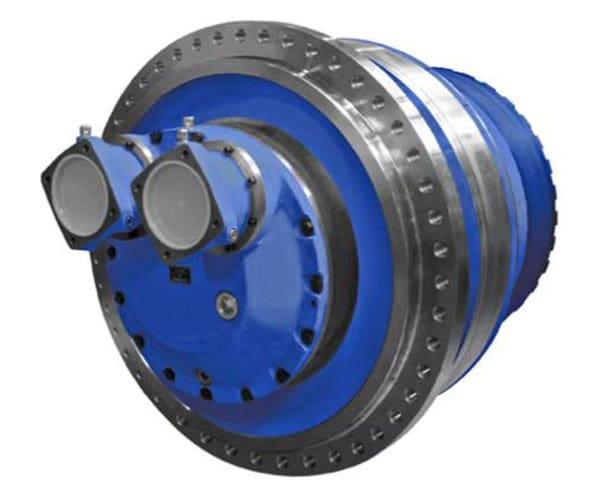

We have supplied 8 units of 930E final drive to China Coal Pingshuo. We repaired 26 units of Hitachi EH3500ACII final drive to China Coal Pingshuo.

Key Factors

Core component supply speed, product quality, and assembly process are essential for equipment maintenance and rebuilding.

R&D and Quality Control

Leveraging our R&D capabilities and quality control expertise to ensure optimal component selection and maintenance.

Global Partnerships

Collaborating with top international suppliers in Europe and America to capitalise on their experience and provide customers with high-quality products and services.

Extensive Experience

Over 20 years of service in the mining industry, backed by a knowledgeable and experienced team.

Upgrading Services

Offering material upgrading, heat treatment optimisation, and tooth shape optimisation to enhance product performance.

Precise Maintenance

Accurate selection of bearing and sealing parts ensures optimised product performance and longevity.

Innovative Maintenance Approach

Implementing new maintenance concepts to optimise equipment performance and reliability.

Upgrade Services

Providing valuable upgrade services to enhance equipment capabilities and longevity.

Cost & Labour Savings

Delivering clear benefits through labour cost reduction and minimised equipment maintenance expenses.

Warranty Assurance

Providing warranties for our components and parts, ensuring customer satisfaction and reliability.

Transmission Assembly Leasing

Offering leasing options for customers as an alternative to purchasing major components.

Improved Service & Efficiency

Meeting customers' maintenance needs while reducing the number of rotating parts, resulting in enhanced service quality.